Hi everyone!

So you’re all trapped in your houses and trying to present a professional and “normal” service?

This method of working had only crossed your mind in your wildest dreams or nightmares right?

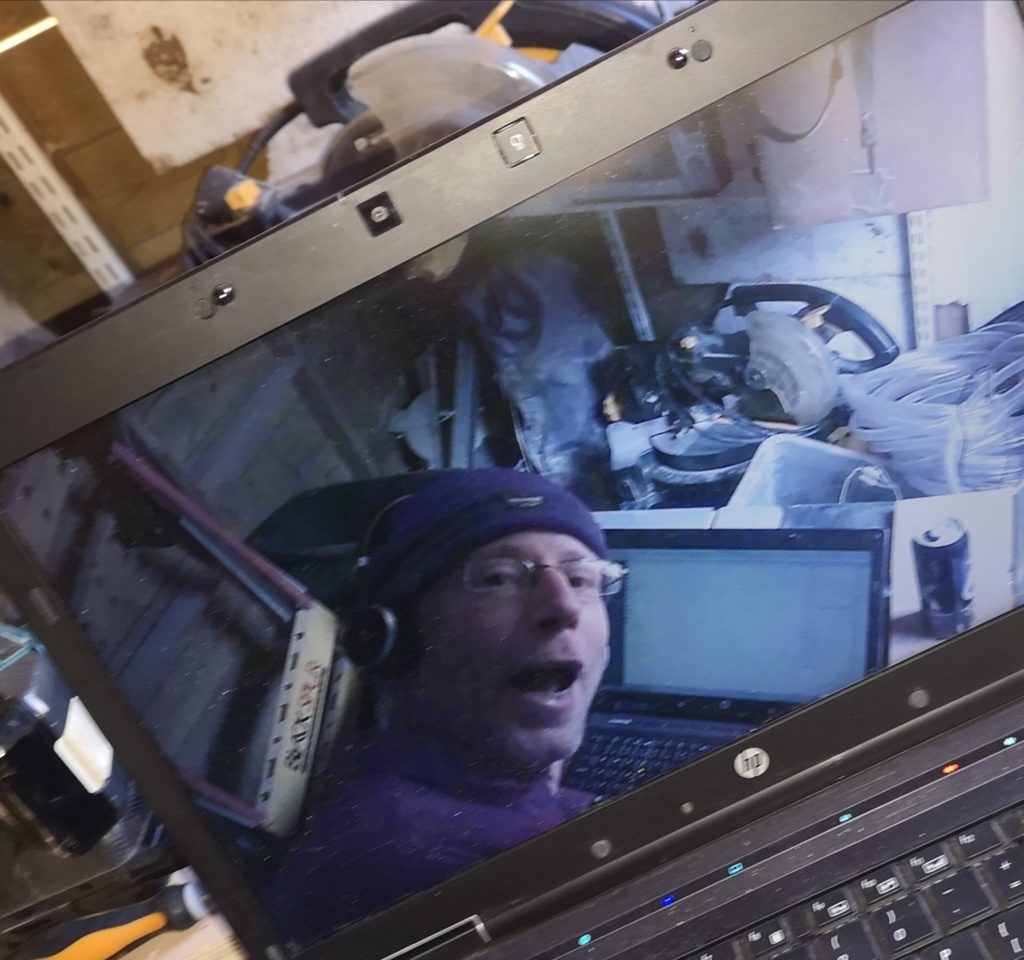

Well I’ve been doing this for years with the work I perform (remote webex configurations or newly install appliance products, normally in remote customer datacentres).

However while my role allows for a scheduled nature and means sitting for hours in front of a laptop, my role isn’t made any different by being at home, a boat, back garden shed or in the office because I’ve adopted certain methods of working.

I wanted to share some to help anyone else and I’m sure many others can share theirs too.

Tip 1: You’re the company.

Not the office, not the fancy clothes, not the new haircut – your skills.

You’re where you are today because you do a great job, you’re motivated and you’re really appreciated.

Yes, if you’re in a video conference – be clothed 🙂

However, generally I try to make sure that I’m not sat next to the doorbell and other loud noises as this, while acceptable mostly, isn’t great if you actually need to hear others.

Tip 2: You have a laptop right?

However health and safety says you shouldn’t sit in front of a laptop for too long as it can cause many nasty things (headaches, back ache, neck ache – the list is horrid) and this forms much of your workstation safety training but they didn’t expect you to only be able to work on the laptop right?

So while the company offers you a screen and other docking station items, your aim shouldn’t be to recreate a place to sit and stare at your screen(s).

I do a generally solitary role (as do my colleagues) but I also need to be seated for up to 5 hours while in a webex with customers.

To this end, if I’m not actively engaged in using the laptop, I’m away from my “desk”.

This means that I can go do other things while monitoring for emails and other items like Instant Messages etc.

Tip 3: Tech is your friend.

However it is only a bunch of tools. Just like any other job (plumber, electrician etc) so you need to think like that about them.

Many company documents are public and online, so use your own favourite tech to check websites and get away from that laptop ??

Here’s a list of tools and how they can be used:

- Laptop – webex, business system access (VPN, VOIP etc). If you don’t have a company mobile, substitute laptop for mobile from here on in and remember – your laptop has a battery, is just a bigger phone and moves too.

- Mobile phone (if you have a company one) – email, instant messaging, calls, texts, photo sharing (basically everything a laptop does except VPN / Business system).

- Wifi: during this time, your home wifi will be contended by every home schooled game console owning child in your region AND everyone’s business traffic.This is seen throughout the world but mainly seems to be functioning.

I strongly recommend getting a MyFi device (a wifi providing mobile internet (3/4/5G) device) as this will allow you to “drop off” the home network and potentially get around contention issues. You’ll appreciate it much more when lockdown ends and you can sail off using it and still be “working from home”.

If you have a good enough personal mobile phone and package, you can generally get by with 30GB a month data sharing on your phone.

Basically, enable your phone’s hotspot and connect your laptop (make sure to be mindful of your data use and most mobile providers have an app to monitor that).

- Headset – probably one of the most used items in your work from home arsenal and you can utilise it in ways you probably haven’t thought of.

As an example. Some headsets now come with the ability to connect to two Bluetooth sources at the same time.

This is great news for the home working masses.

If you’re using your laptop then the headset appears like a normal tool for calls etc. However, also connect it to a music source or tv and watch / listen to music.

When the laptop gets an email, it’ll break the audio and tell you.

Tip 4: Plan to take breaks.

In the office you may have written an email, sent it and got up to get a coffee. Stopping in on your helpful coworker for a quick “hey! You ok?” Type of conversation.

Well you don’t have the coworker now to stop by but you can get up, get coffee, take a quick look at what’s for the next meal, make a list of groceries and then get back to your work.

Taking regular breaks will help you stay mentally healthy. Moving will pump blood, your eyes will need to refocus on different distances and you have got a “home task” started or done.

Tip 5: Loneliness

You’re not really alone. Everyone is pretty much in the same state at the moment – globally.

So accept that things will potentially drop through the cracks, the boss won’t say hello for days, the coworkers that make coffees and teas together with aren’t about.

This is sad if you’re missing these things. However there are things you can do to reduce this.

Make use of, create or just make a pack with your coworkers that you’ll all check in daily (maybe even more than once a day) and stick to it.

Routine is the key here. We all need to be available at the times we normally keep but we can and should make time to have those little chats to coworkers too.

They only need to be the sort of things like “what are you doing?” and the answer doesn’t always need to be work related – it wouldn’t in the office? “I’ve been watching boxsets, working out and making my next shopping list” should be perfectly acceptable too right?

Conclusion

The whole world is with you.

You’re not alone.

You have the tools to be magnificent in times of upheaval but the company NEEDS you to be healthy, happy and customers feel the same.

Yes there are pressures to solve this, research that, tests to run, diagnoses and resolutions to be had.

None of them matter if YOU aren’t ok.

To end, I just want to share my work methods with you via an example day in my role:

I work, as I said, in configuration, installation and some hardware upgrades on a scheduled basis.I’m in a proactive role, not a reactive one so some things will seem odd to the reactive crowd.

I generally work 7.5 hours a day.

I “start” at 7am most days (I’m actually blessed by knowing what the next days schedule is before I sign off each day) and so I’m up and dressed with a coffee in hand by then.

The first tool I pick up is my company mobile (which has been charging all night) and sit at the breakfast table while check my email and calendar for the days events.

I boot my laptop, sign in and open the applications I need for the day (normally a pdf or two, business system and email). I may not need them just yet but they’re then plugged in and left (locked) until I need the laptop.

Once breakfast is done (general conversations with other lockdownees), I respond to any emails I need via my phone and connect my headset to my company mobile and my personal mobile.

I will then go about my day to day routine, work, housework, work, respond to IM etc while listening to either music, learning a skill online or something else on my personal phone.

As I explained before, I am still fully available at all times and because the notifications come from my work phone to the headset, I have no troubles.

With regards to my wife who also works at home now, my step son playing d&d, when not working or college work and my step daughter shouting at the latest YouTube craze – I find a place to work and have done now for circa 10 years (both current role and previous).

Remember; boring people get bored.

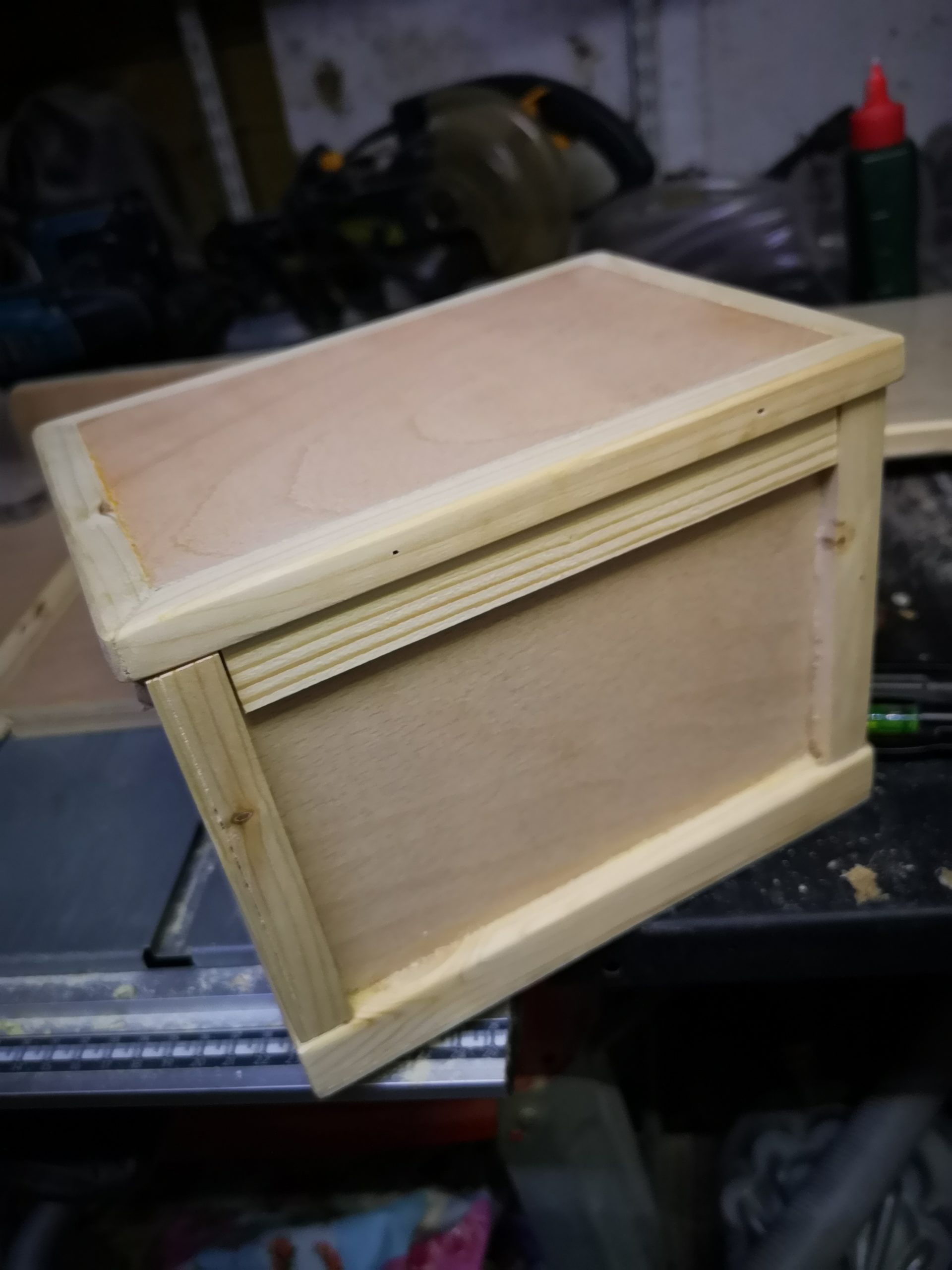

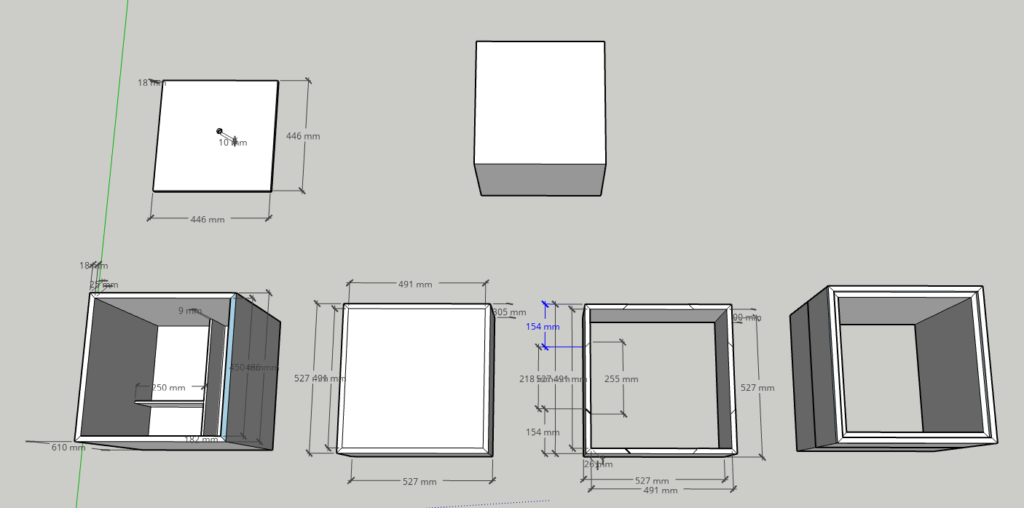

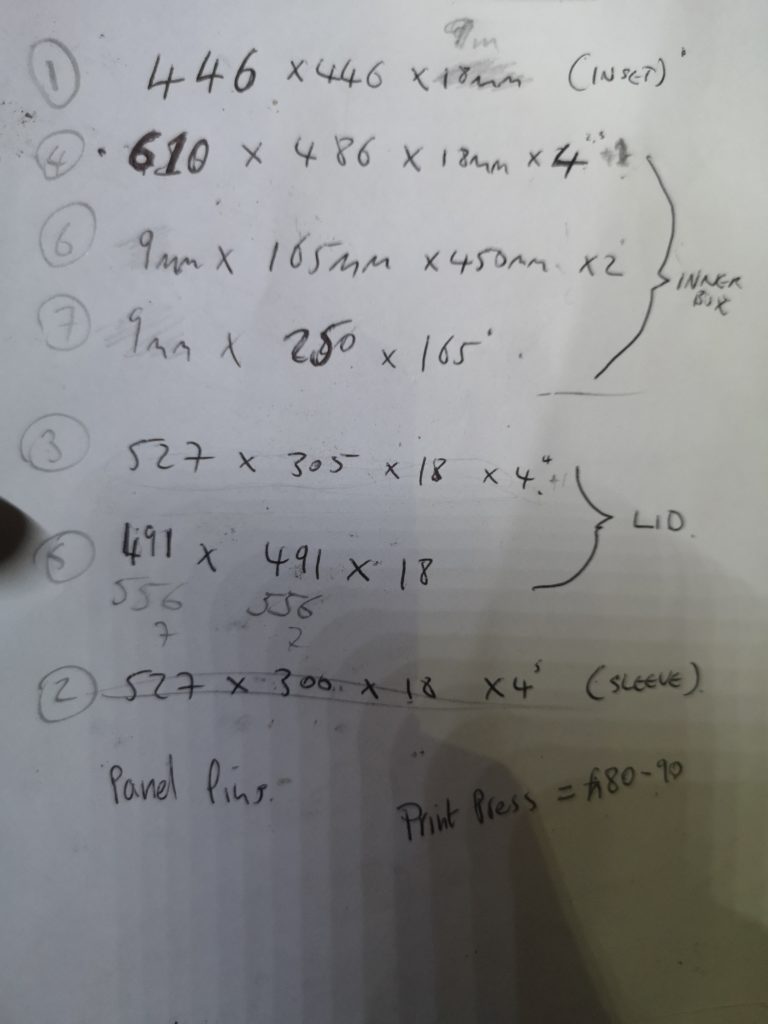

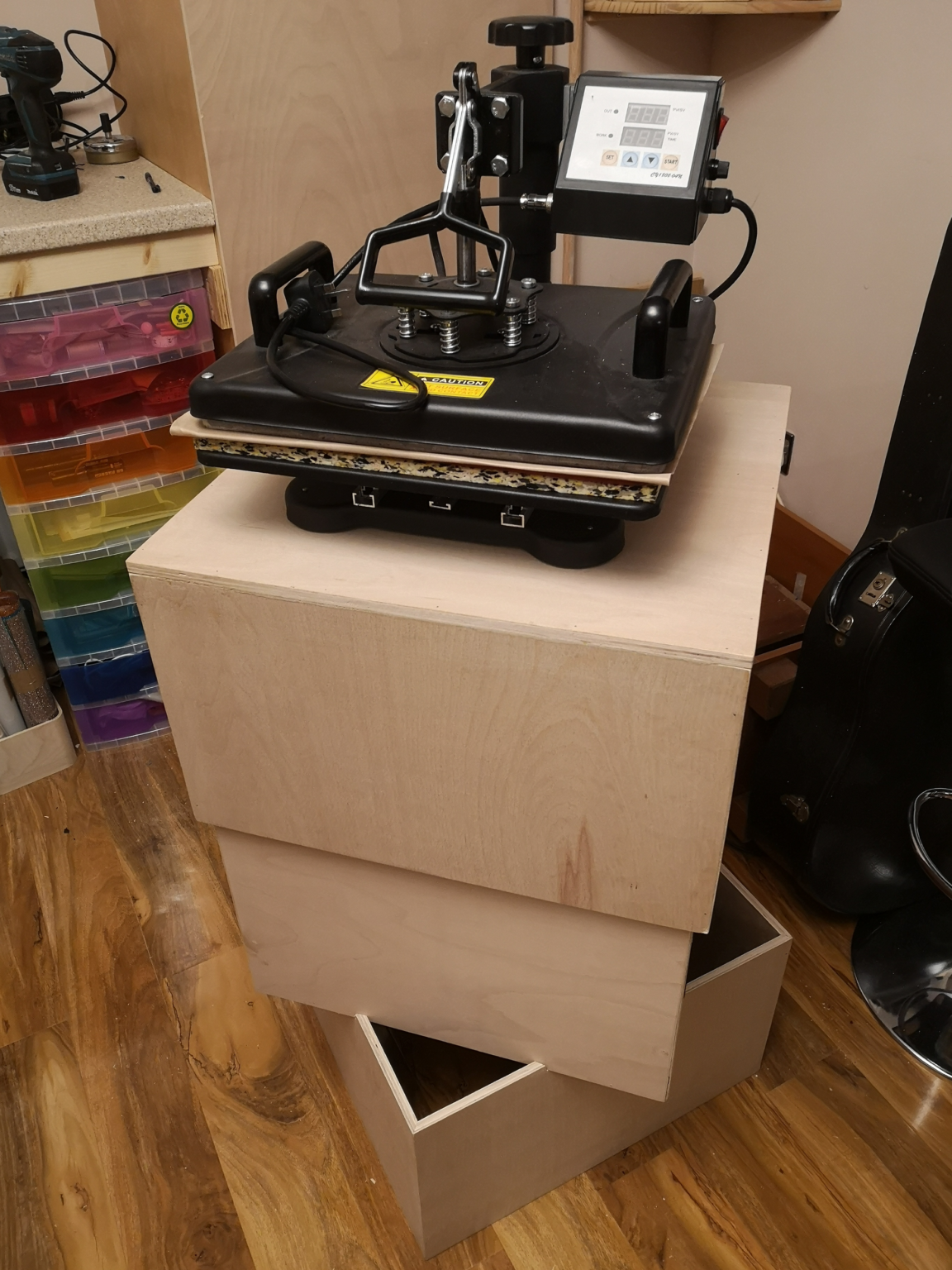

Outside of this, I found that if I find a hobby, I’d be happier. In this lockdown world, I found that making a website and YouTube videos gives me entertainment of an evening and I welcome you to join in www.linked2u.co.uk where I’ve been making and filming / blogging various hobbies I’ve tried out.

Stay safe and well all!